MSU Single Flute End Mill For Wood Mdf Plastic Acrylic -Square -Upcut

- group name

- End Mill For Wood

- Min Order

- 1 piece

- brand name

- MSUTOOLS

- model

- D1mm-20mm

- Nearest port for product export

- Any ports of China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Credit Card, PayPal, Westem Union

- update time

- Sat, 07 Aug 2021 18:35:22 GMT

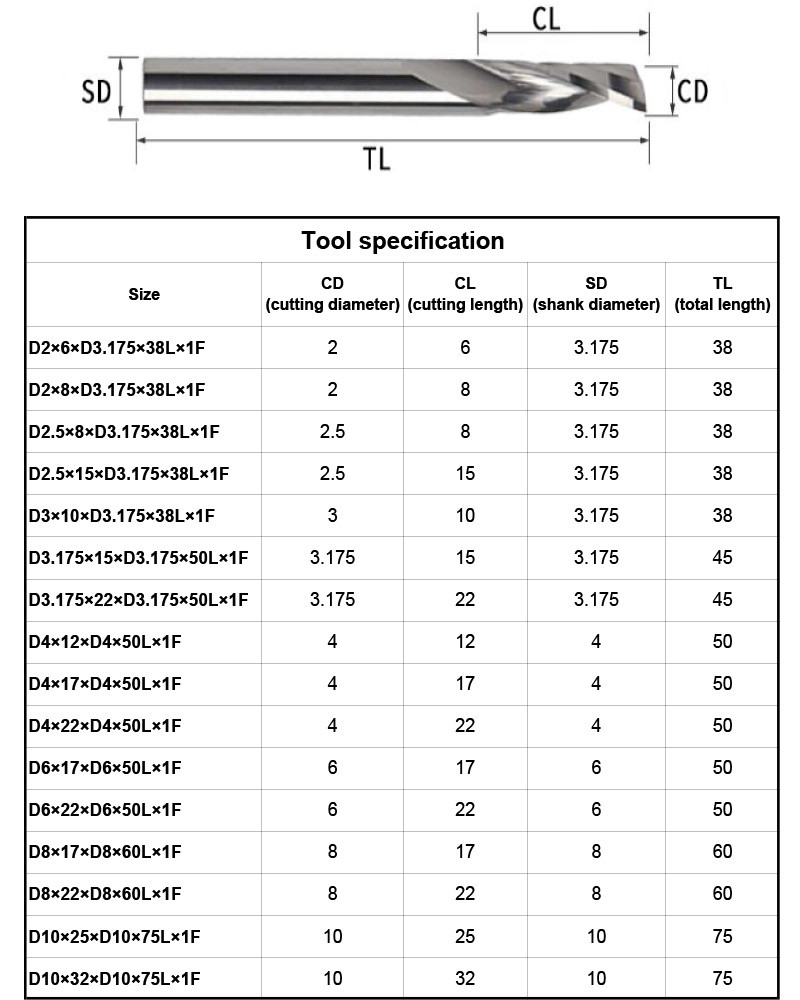

Paramtents

Material Solid Carbide

Internal Cooling Without

No of Cutting Flute One

Type Flattened

Coating Uncoated

Cutting Direction Right - Hand

Helix Angle 25°

Precision ±0.01

Workpiece Wood Mdf Plastic Acrylic

Application Milling

Cutting Diameter 1mm-20mm

Full Length 50mm/75mm/100mm/150mm

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

|

Description

|

MSU Single Flute End Mill For Plastic Aluminum -Square -Upcut

|

||

|

Hardness

|

HRC58

|

||

|

Coating

|

Uncoated

|

||

|

Helix Angle

|

25°

|

||

Workpiece | Wood Mdf Plastic Acrylic | ||

Application | Side Milling and Face Milling/Slotting | ||

This offering of End Mills for Plastics -

Square Upcut - Single Flute results in twice the material removal with improved

finish over standard end mills. The high rake, high relief design of this tool

produces a sharper edge for improved shearing action while transferring heat

into the chip.

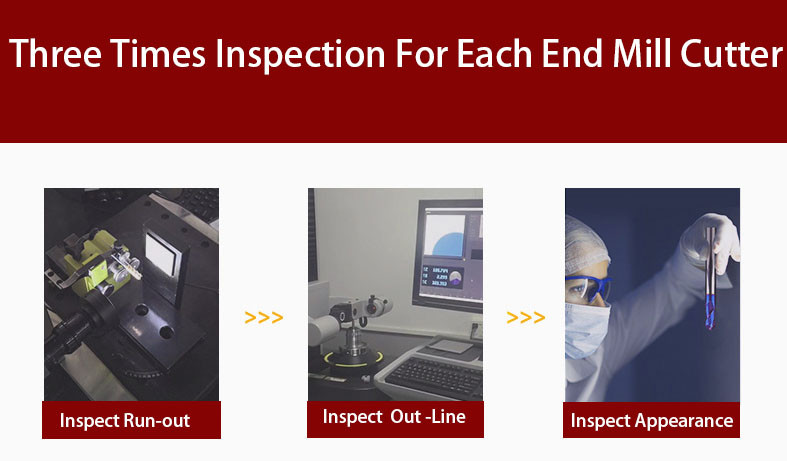

All End Mills are made by 5 Axis CNC machines such as ANCA/Walter, the end mills come to be high precision, long working life, high efficiency. | |||